Customised pipes

isoplus is able to supply a number of products in addition to those found in our catalogue and brochures. Contact isoplus’ technical department and let us find the right solution for your project.

Sometimes a project calls for custom-made solutions that are specifically made to fit the needs of your project. For example, if you need pipes to be placed above ground level or in areas affected by permafrost, pre-insulated customised pipes can be the right solution.

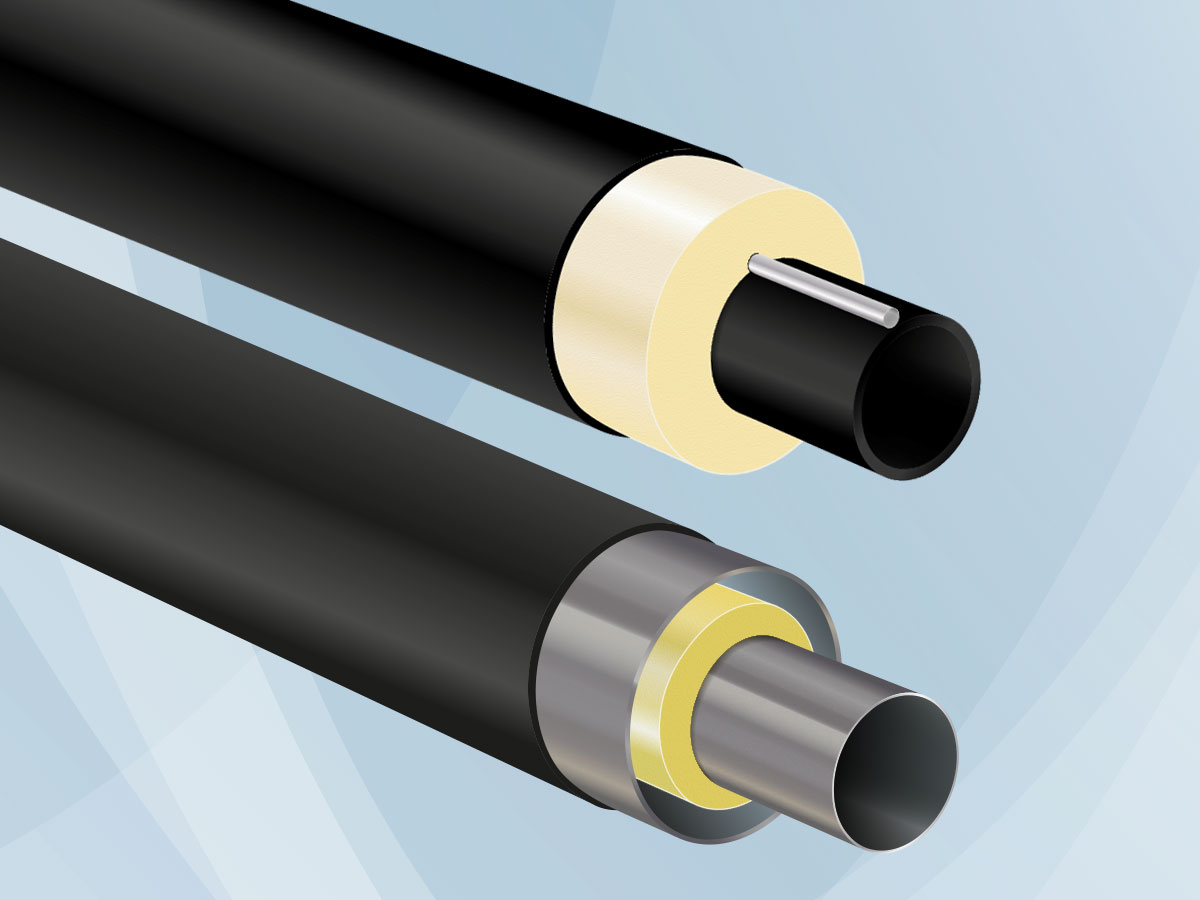

With pre-insulated customised pipes, there is no standard solution that suits everyone, since a customised pipe is an assembly of several different components and is made to fit the needs of your project. The specific solution will be individual, but usually it is the intended use of the product that determines which components are assembled. However, pre-insulated customised pipes are most often used when it comes to special requirements in terms of the installation environment, media, temperature load and/or pressure.

Components for customised pipes

There are many different combinations, but the typical components for pre-insulated customised pipes are:

Carrier pipe:

- Welded black steel (besides P235GH)

- Black steel with increased wall thickness

- Seamless pipes

- Stainless acid-resistant steel

- HDPE

Jacket pipes:

- HDPE jacket pipe with increased wall thickness

- Spiro jacket pipe

- White HDPE

Insulation:

- Mineral wool

- Mineral wool and PUR combined

Tracers:

- Copper

- HDPE

- Aluminium

Examples of projects with pre-insulated customised pipes from isoplus

isoplus has delivered preinsulated customised pipes to, for instance, a system provider to the food industry. For establishing an indoor piping for hot frying oil, they needed a pipe that was approved for foodstuffs and could resist extremely high temperatures. The solution was provided with the help of isoplus’ technical department and consisted of seamless pipes, insulated with mineral wool in a white HDPE jacket pipe.

Another example is when a brewery needed to install steam and condensate lines to which isoplus delivered preinsulated customised pipes. The customer asked for frost-proof pipes. However, after a review of the project, it was decided that tracers were not required after all. Thanks to isoplus’ expertise they came up with a solution that involved a high-temperature line consisting of seamless carrier pipes and an insulation of mineral wool combined with PUR as well as a condensate line consisting of seamless carrier pipes with standard PUR insulation.

Application

District heating, district cooling, solar heating, community heating, industry

At isoplus you can always get professional support from project start until the piping system is installed.

We can help with turnkey solutions, planning, design calculations, feasibility study, trenchless technology, tool hire, alarm report, planned preventative maintenance, installation of joints and installation of leak detection system.

Read more about isoplus service & support.