Waste management

This has been achieved by:

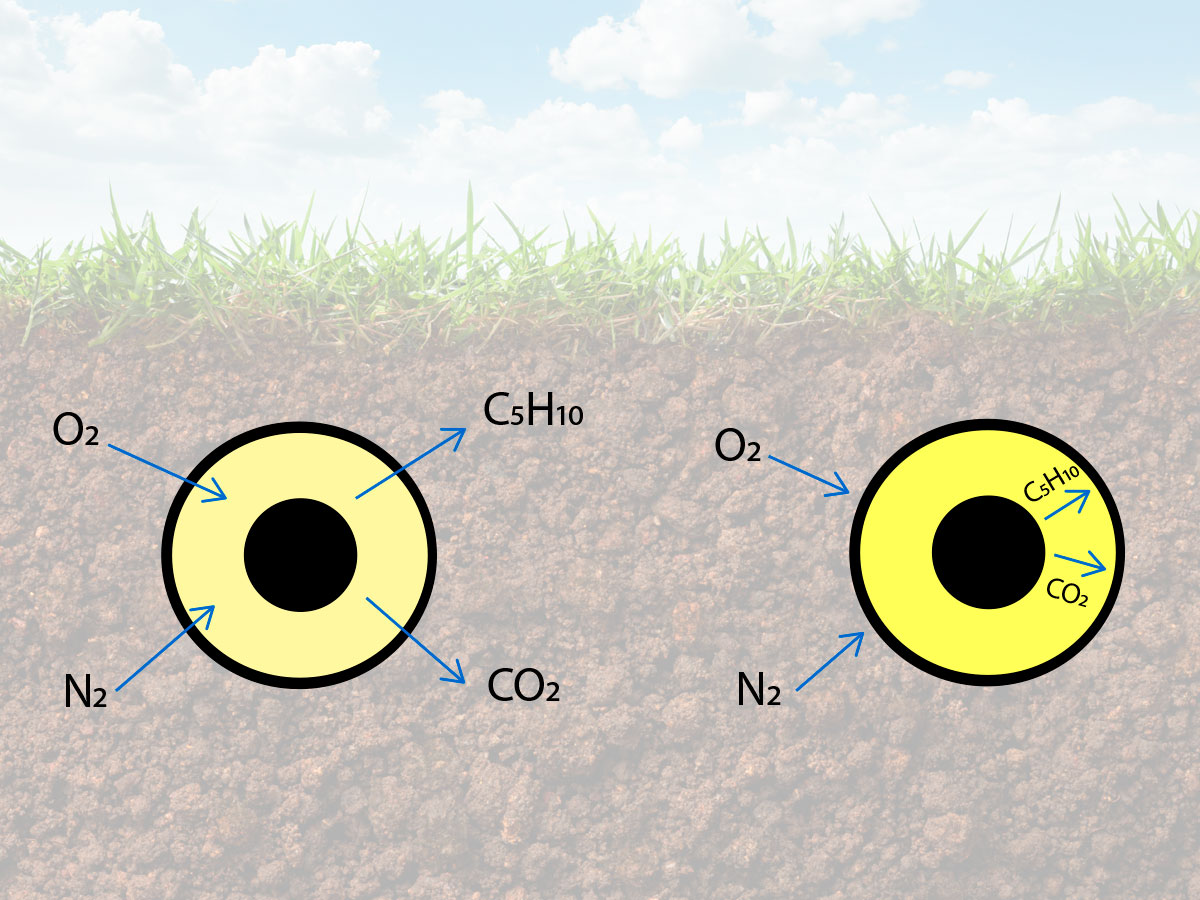

- Using C-pentane – the most environmentally friendly blowing agent currently available for foaming purposes

- Minimising the use of packaging materials and avoiding unnecessary packaging

- Adopting specific work environment plans for individual production employees and individual production facility

Thanks to such measures, isoplus has succeeded to reduce its production of waste materials to extremely low levels. The company also adopted waste handling and disposal procedures to minimise environmental impact.

Cured foam components are delivered to incineration plants or other approved disposal sites.

Fluid foam components are collected by local waste disposal firms which are approved for handling toxic wastes. No solvents are used in our production processes.

About isoplus

Since the company’s foundation in 1993, we have kept up to date with the development and researched new technologies to provide the best, most efficient and most sustainable solutions for district heating and district cooling.

Organisation

isoplus Denmark is a part of the isoplus group, which includes separate production sites and sales companies all over Europe.

Quality assurance

Quality assurance (QA) is of paramount importance to the isoplus group. To ensure continuous quality assurance at the highest level, all production facilities are certified according to ISO 9001.

Environment & sustainability

isoplus constantly works to ensure that current environmental requirements are met everywhere in the isoplus group.