Insulation

The use of polyurethane foam (PUR) – consisting of polyol and isocyanate – is common in all isoplus piping systems, regardless of carrier pipe type. With lambda values as low as 0.022, polyurethane foam is one of the most efficient insulation materials. The extremely low heat conductivity of polyurethane ensures reliable insulation and low heat loss throughout the service life of the system.

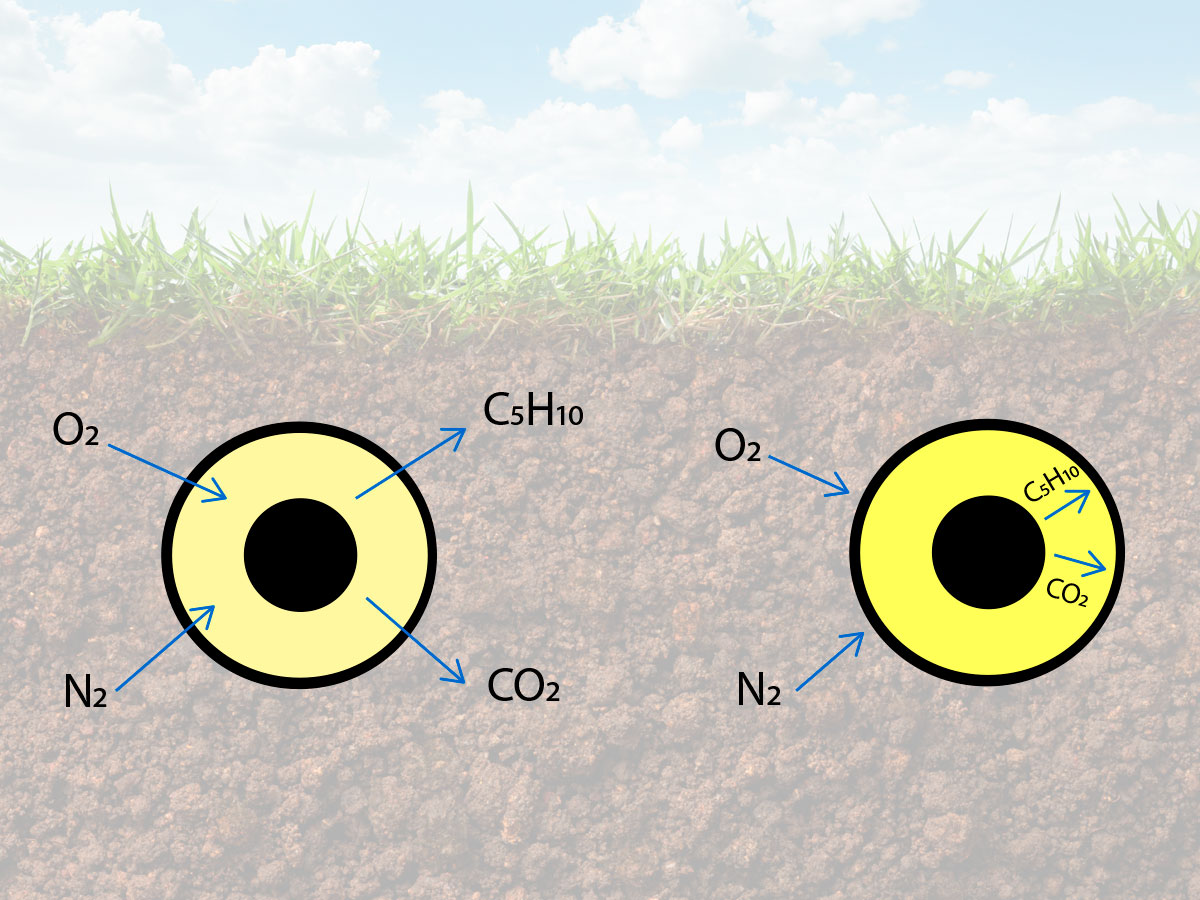

Heat conductivity and insulation quality depend on the cell gas in the polyurethane foam. Keeping the gas inside the jacket pipe is therefore essential for the long-term thermal properties of the piping system.

Most isoplus pipes up to dimension ø355 mm are provided with a diffusion barrier between insulation and jacket pipe. The barrier prevents decomposition of the foam and protects our pre-insulated pipes from ageing.

Thanks to increased wall thickness, jacket pipe dimensions ø355 mm and larger provide natural diffusion barriers.

Jacket pipe material

We use jacket pipes of polyethylene (PE) to protect the polyurethane foam insulation.

To ensure a high quality of the jacket pipe, we use raw materials from approved manufacturers only.

For traditional manufacture of straight pipes, we use high-density PE, HDPE. HDPE jacket pipes are mainly manufactured in our own extruders.

To ensure high flexibility, we use low-density PE, LLDPE, for continually produced flex pipes. During the continual production, the jacket pipe is extruded continually onto the outside of the foam insulation.