District cooling

District cooling is becoming increasingly more important all over the world. Also in Denmark district cooling schemes are being established. The basic principle of district cooling is similar to that of district heating. A carrier medium is cooled centrally and the cooling is distributed to the customer through a pre-insulated piping system.

Centralised district cooling produces a more cost-efficient system than cooling produced in small decentral units. Put simply you get more cooling for your money. Often, it is also possible to use various energy sources, like surplus heat from power production or industrial processes that would otherwise go to waste. Other heat sources such as waste incineration and geothermal energy can also be converted to district cooling.

The operating temperature of a district cooling system is typically between 5°C and 12°C. However, cooling media with extremely low temperatures, for example from the chemical industry, can also be transported.

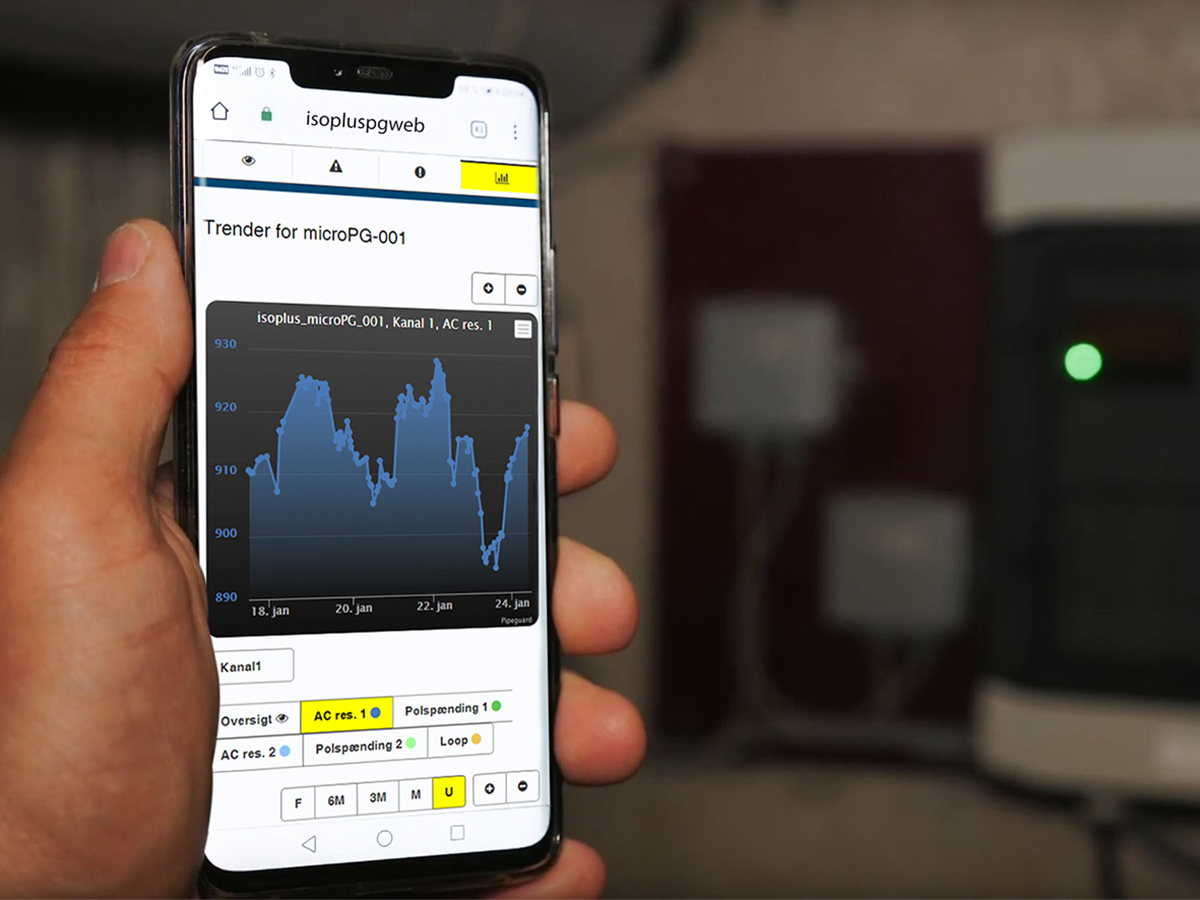

isoplus develops pre-insulated pipes and components for district cooling, which ensure a minimum of heat loss from the piping system and make your district cooling system future-proof.

We help you find the best and most cost-effective solution for your project.

Pipes and fittings for district cooling

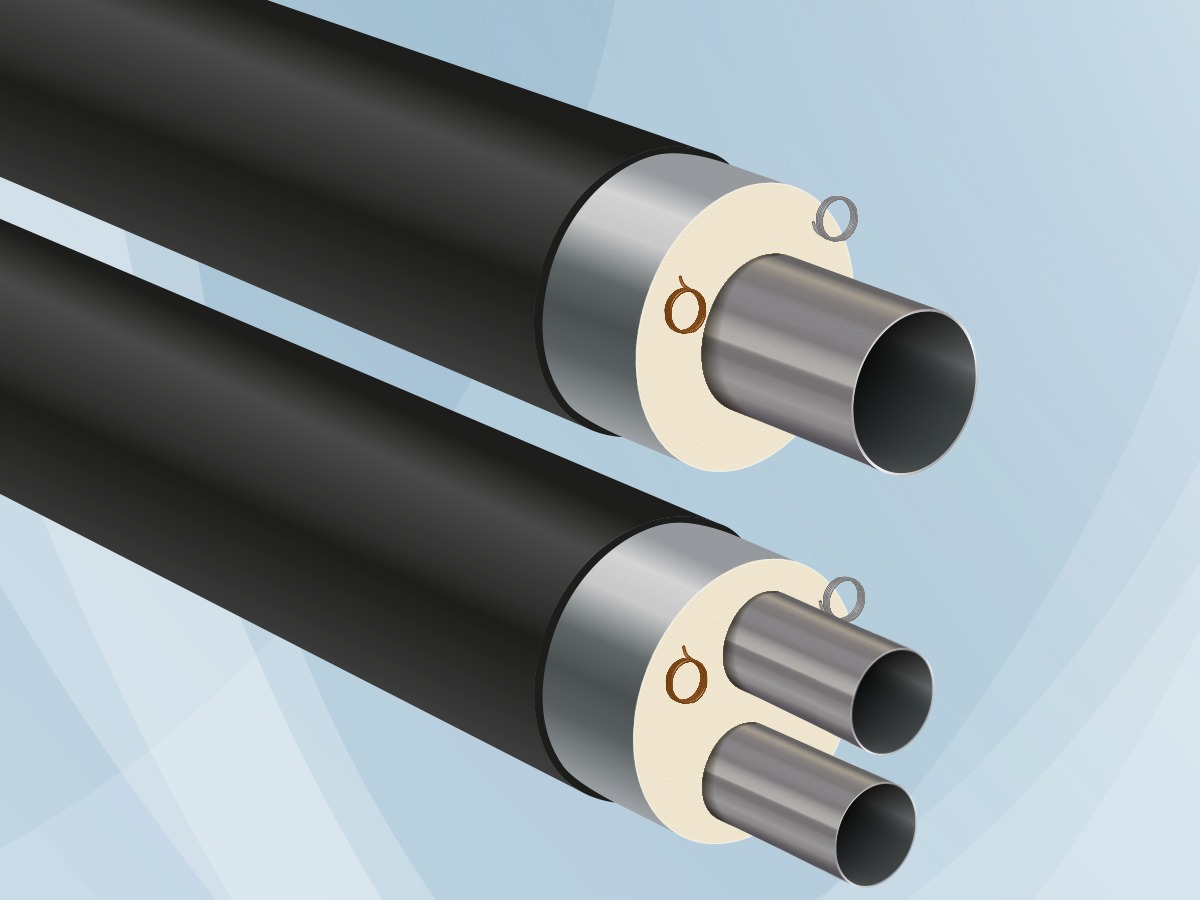

Steel pipe

Pre-insulated steel pipe is a solid and efficient solution for district heating, cooling as well as industrial applications that require high temperature and pressure resistant pipes.

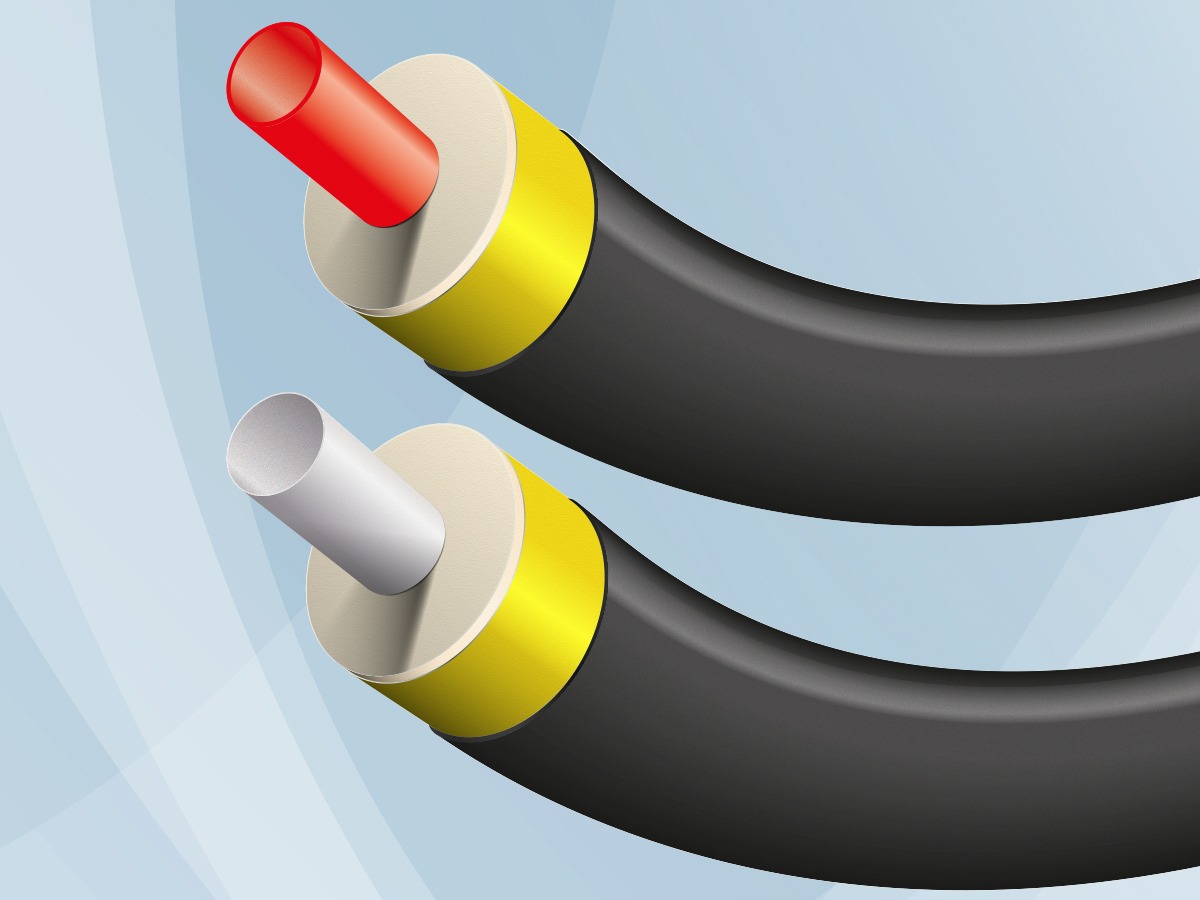

isopex

isoplus pre-insulated isopex pipes are perfectly suited for branch lines, secondary lines and small community projects with a continuous operating temperature of maximum 85°C.

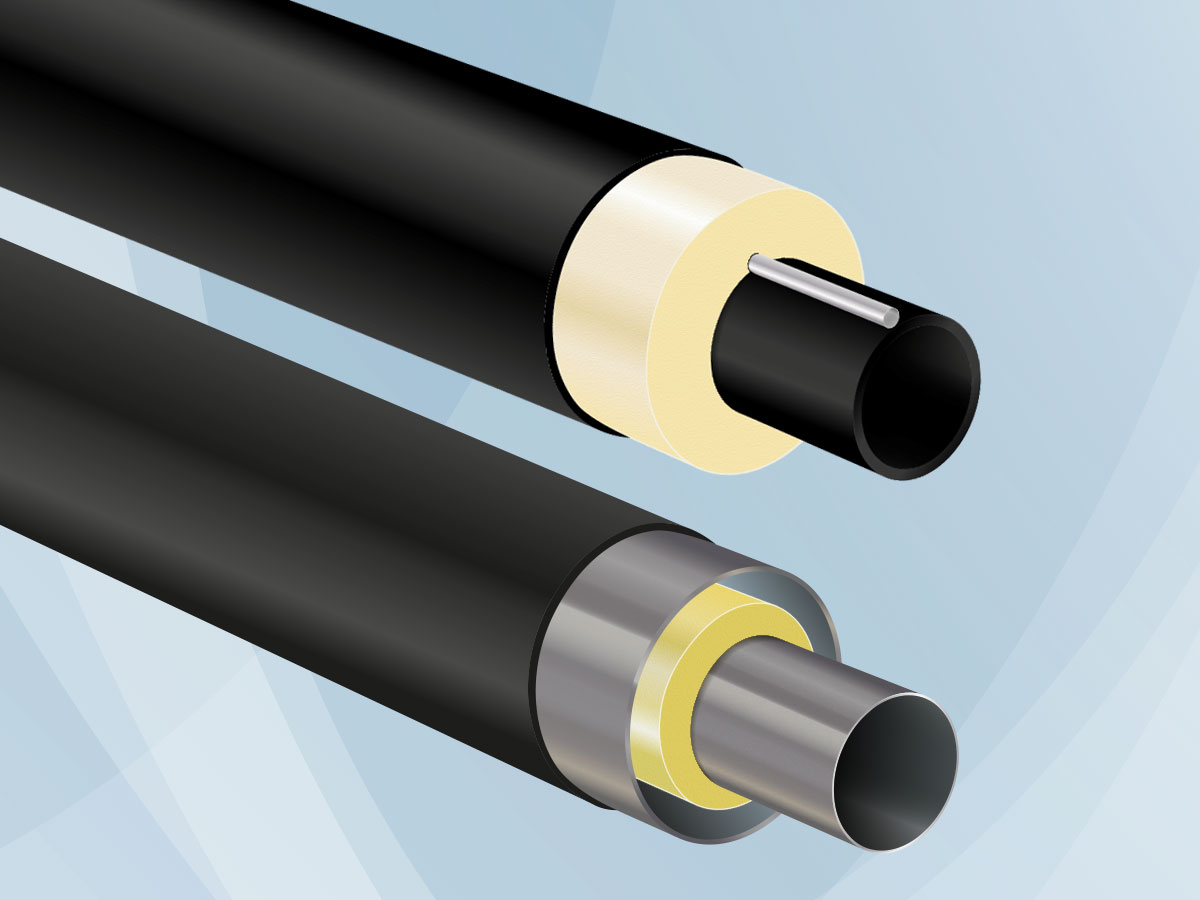

isoclima

isoclima is a flexible pipe system made of fracture and impact resistant HDPE, particularly suited for the transport of cold water.

Customised pipes

isoplus is able to supply a number of products in addition to those found in our catalogue and brochures. Contact isoplus’ technical department and let us find the right solution for your project.