Quality assurance

Our QA systems cover all the company’s processes, including production, planning and design. Product installation is also covered when performed by isoplus.

isoplus’ quality engineers work to constantly ensure that everything goes according to plan. In addition, they help determine and calculate safety beyond current standards.

The isoplus group does not only adhere to the EN norms EN253, EN448, EN488, EN489, EN13941, EN14419, EN15632 and EN15698 – we gladly take it one step further to increase the safety level even further.

Before any raw materials are used, they receive production release approval on the basis of a comprehensive incoming goods inspection in accordance with EN 253. We regularly take samples for laboratory analysis. Our approved suppliers must comply with the guidelines contained in ISO 9001 and must be able to submit all required and necessary test certificates.

During production, and on completion of a work process, all our employees are required to check their work in relation to current work descriptions and quality plans. Continuous testing and inspection by independent quality control agencies ensure that all our QA systems and guidelines operate as intended.

About isoplus

Since the company’s foundation in 1993, we have kept up to date with the development and researched new technologies to provide the best, most efficient and most sustainable solutions for district heating and district cooling.

Organisation

isoplus Denmark is a part of the isoplus group, which includes separate production sites and sales companies all over Europe.

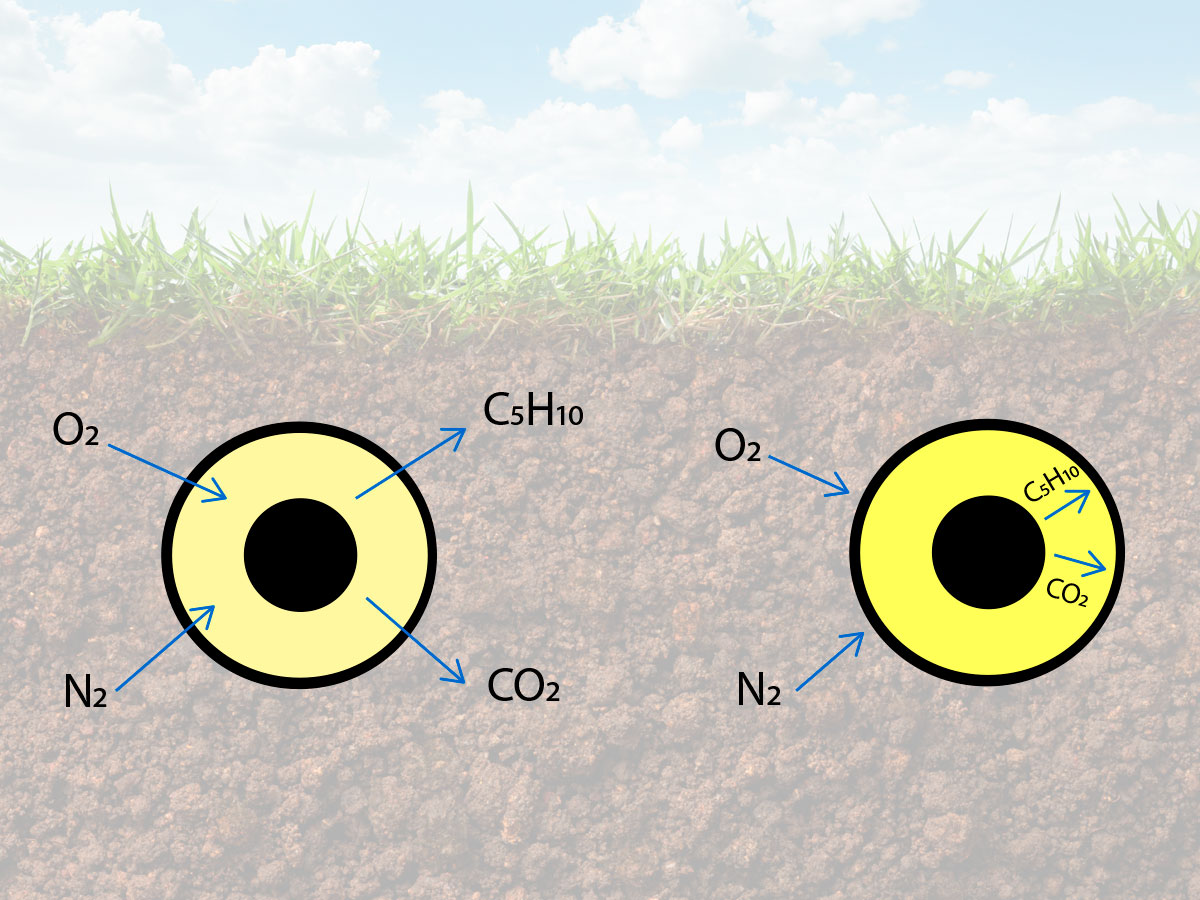

Environment & sustainability

isoplus constantly works to ensure that current environmental requirements are met everywhere in the isoplus group.

Waste management

Manufacturing of pre-insulated pipe systems generates a minor amount of residual waste, which is subject to clear disposal procedures.